Router Table

Contents

Router Operation

The router installed in the table is a 3-1/4 HP Porter Cable 7500 series router equipped with speed control and soft start.

To change the bit, raise the router (see below) all the way up and use the included wrenches.

The router is equipped with speed control. In general, smaller diameter bits will require a faster speed and larger diameter cutters will require a slower speed.

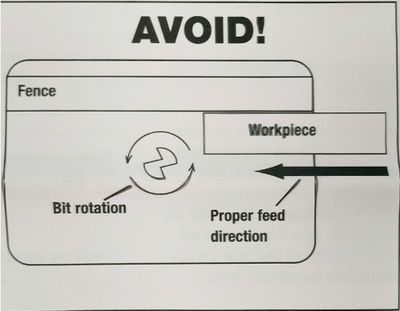

Always feed the workpiece against the cutter rotation. When using the fence, this is right-to-left.

Table Operation

The table is equipped with a Rockler Pro router lift. Using the included tool, the router is raised and lowered from above the table. The table is also equipped with a fence which can be shimmed (shims included) to perform jointing operations.

Raising and Lowering the Router

Insert the crank handle into either the fast or fine adjustment holes in the router table. Turn clockwise to raise, counter-clockwise to lower. The fine adjustment hole has an indicator on it which can be zeroed out by simply spinning the thumbwheel until the 0 lines up with the line in the plate.

Starter Pin

The table is equipped with a starter pin which is to be used when the fence is not being used. According to Rockler:

Stock is most vulnerable to catching and being thrown at the beginning of the cut, before it engages the router bit's guide bearing. Install the Starter Pin, which consists of a round-head bolt through a non-marring plastic sheath, into the mounting hole in the Pro Lift Plate. Then use the Starter Pin as a fulcrum to feed your workpiece into the bit.

Fence

While using the fence, make sure to avoid "fence traps". Additionally, ensure that the bit guard is positioned over the bit at all times.

Fence Setup

Position the fence as close to the bit on both sides as possible without contacting the bit. The fence material is MDF and is not dangerous if it contacts the bit but care should be taken so as not to damage the fence.

Jointing

It is possible to perform a jointing operation on the router table. According to Bench Dog:

Jointing on a router table is not intended to replace a free standing power jointer, especially for stock wider than 1.25". However, jointing with the router table does have advantages over the jointer. First, small and short pieces of wood can be safely jointed because the opening of the fence can be made very small: about 1/2". Second, the quality of the cut is usually better because the router bit spins much faster than the jointer's cutter head. A faster cutter speed is especially useful on woods prone to tear-out, like bird's eye maple and quilted cherry. Be sure not to move too slowly, as this will leave burn marks in your workpiece.

Jointing is performed using a 1/2" diameter straight or spiral up-cut bit with 1/2" shank. The bit's cutting length must not exceed 1.25". Set the bit height to 1.25" or less.

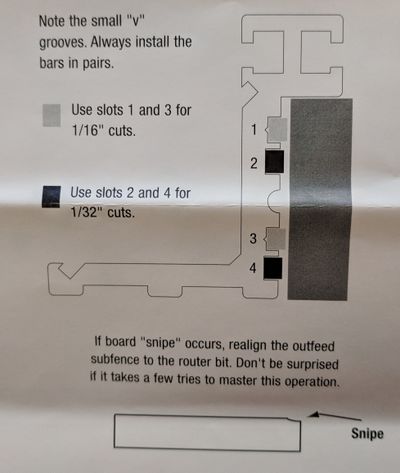

Jointer bars are used to space out the MDF subfence to support the material on the outfeed (left) side of the fence. Install the jointer bars under the MDF subfence in the slots of the aluminum fence. The slots with "v" grooves are for 1/16" cuts while the slots without grooves are for 1/32" cuts. Use a straight edge to line the cutting edge of the router bit with the outfeed surface. It is advised to make a test cut to check alignment.