Difference between revisions of "Industrial Sewing Machines"

(Created page with "==Machine Tips== *Needle type for all materials besides leather - 135x17 *Leather needle type - 135x16 *Using a regular needle on leather can rip the leather or leave holes *...") |

Ron.Thomas (talk | contribs) |

||

| Line 88: | Line 88: | ||

What to do if the machine locks up? This usually occurs when thread is stuck in the bobbin area and the safety clutch engages to prevent further damage. | What to do if the machine locks up? This usually occurs when thread is stuck in the bobbin area and the safety clutch engages to prevent further damage. | ||

| − | Press the button on the bed and turn the wheel backwards until you hear a click. | + | Press the button on the bed and manually turn the wheel backwards until you hear a click. |

Revision as of 17:29, 17 January 2017

Contents

Machine Tips

- Needle type for all materials besides leather - 135x17

- Leather needle type - 135x16

- Using a regular needle on leather can rip the leather or leave holes

- Bobbin - type M

Before You Sew

You must be certified on this machine to use it. Look for a certification class on MeetUp or refer to the sewing Slack channel (#sewing-embroidery).

Choose the appropriate thread size for your selected needles. Use the excellent chart below to determine what size thread to use. If you are sewing leather, you will probably be using a size 16 or 18 needle. You can refer to this document if you are interested in learning more about needle to fabric pairings. As a further reference, but sure to look into the Coats Information Hub.

| Thread Size | Needle Size |

| 33 | 14-16 |

| 46 | 18-19 |

| 69 | 20-21 |

| 92 | 20-22 |

| 138 | 22-24 |

| 207 | 24-26 |

| 277 | 26-28 |

| 346 | 26-28 |

| 415 | 30 |

Preparing the Machine for Sewing

Threading the Bobbin

Threading the bobbin can take place while sewing but does require a second cone of thread. The lever pops up when the bobbin is full.

Threading the Machine

Refer to the photos below to determine the pathway of the thread.

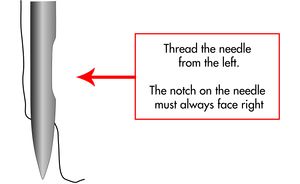

Inserting the Needle

Push the needle up as far as it will go. Thread goes from left to right.

Incorrectly inserted needle will cause thread breakage and possible needle breakage as well.

If the thread is breaking a lot, it’s time to replace the needle. It is recommended to replace the needle after 8 hours of sewing time.

Changing the Foot

When changing the feet, push the front foot up on the shaft until it stops. Before tightening the screw, use screwdriver to gently pry apart the opening to slide the foot up the shaft. It prevents skipped stitches and mis-feeds on the material.

Troubleshooting

What to do if the machine locks up? This usually occurs when thread is stuck in the bobbin area and the safety clutch engages to prevent further damage.

Press the button on the bed and manually turn the wheel backwards until you hear a click.