Difference between revisions of "Soldering"

Lynne.Davis (talk | contribs) |

|||

| (3 intermediate revisions by 2 users not shown) | |||

| Line 10: | Line 10: | ||

In contrast, soft soldering or just plain soldering (such as is commonly used in electronic connections) is the same, except the joining third metal material has | In contrast, soft soldering or just plain soldering (such as is commonly used in electronic connections) is the same, except the joining third metal material has | ||

| − | a melting point less than about 840F. It uses a different alloy which lowers the melting temp. | + | a melting point less than about 840F. It uses a different alloy which lowers the melting temperature to a point where a torch is not required and a soldering iron is preferred. |

| + | |||

| + | ==Notes from a session on brazing with Mike Thomas== | ||

| + | * Clean the joint like for soldering | ||

| + | * Brass brazing rod is alloyed with tin which helps it liquify and flow | ||

| + | |||

| + | * Flux - hand-i-flux (has borax) for brazing or silver soldering | ||

| + | |||

| + | * Two torches can be used to add more heat (BTUs) to make work piece hotter. When workpiece reaches the temp of the brazing rod (brass) the brass melts and fuses the joint. | ||

| + | [[File:Brazing.jpg]] | ||

| + | * If the brass rod gets too hot, the tin can burn off and it won’t be able to flow properly to braze the join. Heat evenly so two pieces to be joined come to temp (cherry-red) together. | ||

| + | |||

| + | ''Also…'' | ||

| + | * Welding rod is steel plated with copper to keep it from rusting | ||

| + | * Material to be welded does not have to be as clean as for brazing/soldering | ||

| + | * Stick welding is similar to MIG welding and is faster (hotter) than gas welding. | ||

==Resources:== | ==Resources:== | ||

| Line 16: | Line 31: | ||

:[http://www.fusion-inc.com/brazing/silver-brazing/ Silver Brazing Explained] from Fusion.inc.com | :[http://www.fusion-inc.com/brazing/silver-brazing/ Silver Brazing Explained] from Fusion.inc.com | ||

:[https://app.aws.org/wj/2000/09/0015/ Ten Reasons to Choose Brazing] From W. Daniel Kay, American Welding Society | :[https://app.aws.org/wj/2000/09/0015/ Ten Reasons to Choose Brazing] From W. Daniel Kay, American Welding Society | ||

| − | |||

Latest revision as of 00:00, 17 October 2017

Soldering and Brazing Defined[edit]

Soldering has a long history and the term is often used to mean different things. The term 'soldering' in jewelry is conventionally understood to mean hard soldering or silver brazing. There is basically no distinction in industry betweeen the following terms which are are used interchangeably:

- Silver soldering

- Silver brazing

- Brazing

- Hard soldering

And the salient points are: two similar or dis-similar metals being joined by a third metal with a melting point over about 840F. Jewelry typically uses this type.

In contrast, soft soldering or just plain soldering (such as is commonly used in electronic connections) is the same, except the joining third metal material has a melting point less than about 840F. It uses a different alloy which lowers the melting temperature to a point where a torch is not required and a soldering iron is preferred.

Notes from a session on brazing with Mike Thomas[edit]

- Clean the joint like for soldering

- Brass brazing rod is alloyed with tin which helps it liquify and flow

- Flux - hand-i-flux (has borax) for brazing or silver soldering

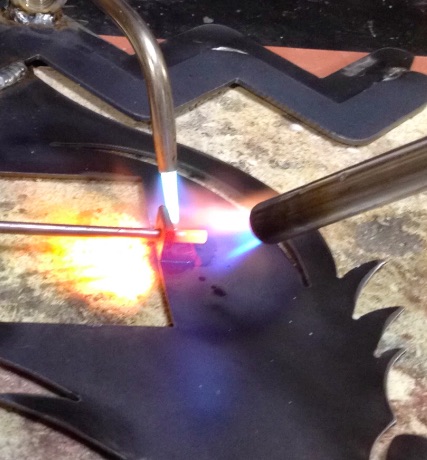

- Two torches can be used to add more heat (BTUs) to make work piece hotter. When workpiece reaches the temp of the brazing rod (brass) the brass melts and fuses the joint.

- If the brass rod gets too hot, the tin can burn off and it won’t be able to flow properly to braze the join. Heat evenly so two pieces to be joined come to temp (cherry-red) together.

Also…

- Welding rod is steel plated with copper to keep it from rusting

- Material to be welded does not have to be as clean as for brazing/soldering

- Stick welding is similar to MIG welding and is faster (hotter) than gas welding.

Resources:[edit]

- Silver Brazing Explained from Fusion.inc.com

- Ten Reasons to Choose Brazing From W. Daniel Kay, American Welding Society